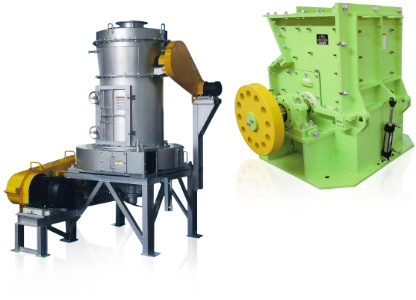

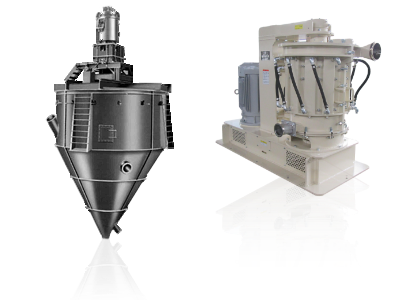

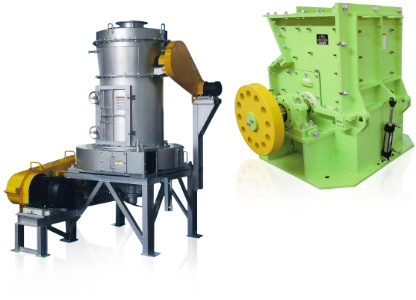

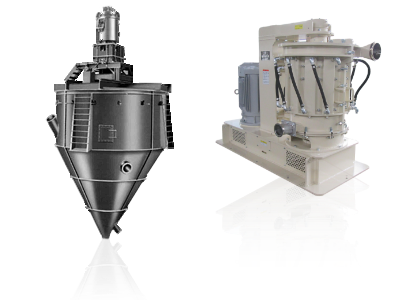

製品情報 PRODUCT

お知らせ INFORMATION

創業100年

以上の実績

ご要望に応じた

機械のご提案

リピーター

のお客様多数

多種多様な

業界への納入実績

海外への納品実績

25カ国以上

創業100年

以上の実績

ご要望に応じた

機械のご提案

リピーター

のお客様多数

多種多様な

業界への納入実績

海外への納品実績

25カ国以上